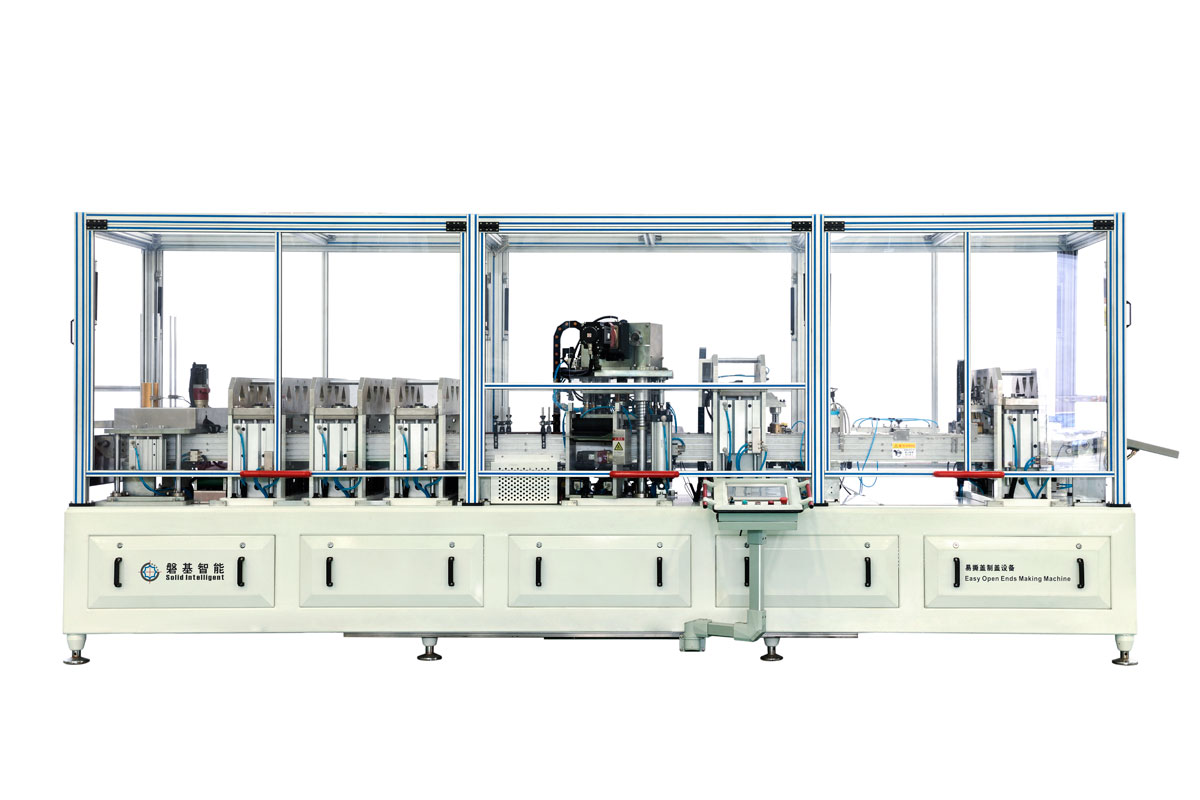

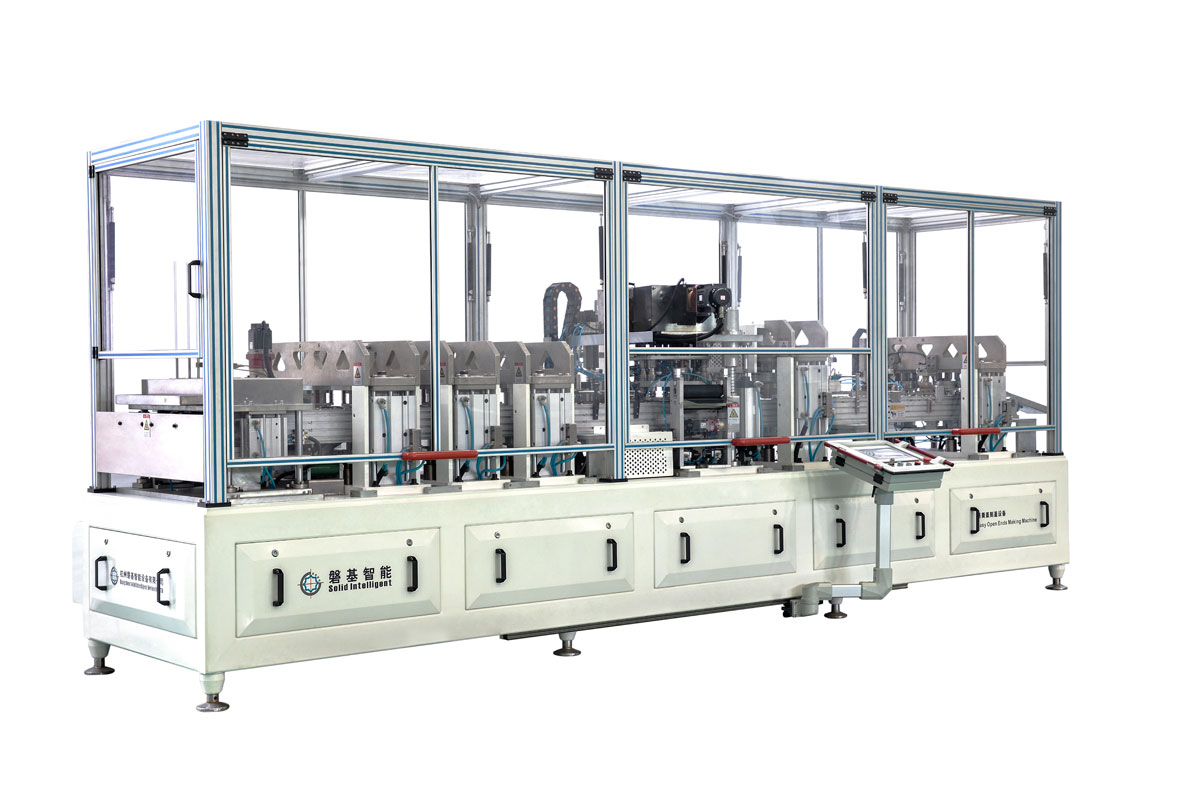

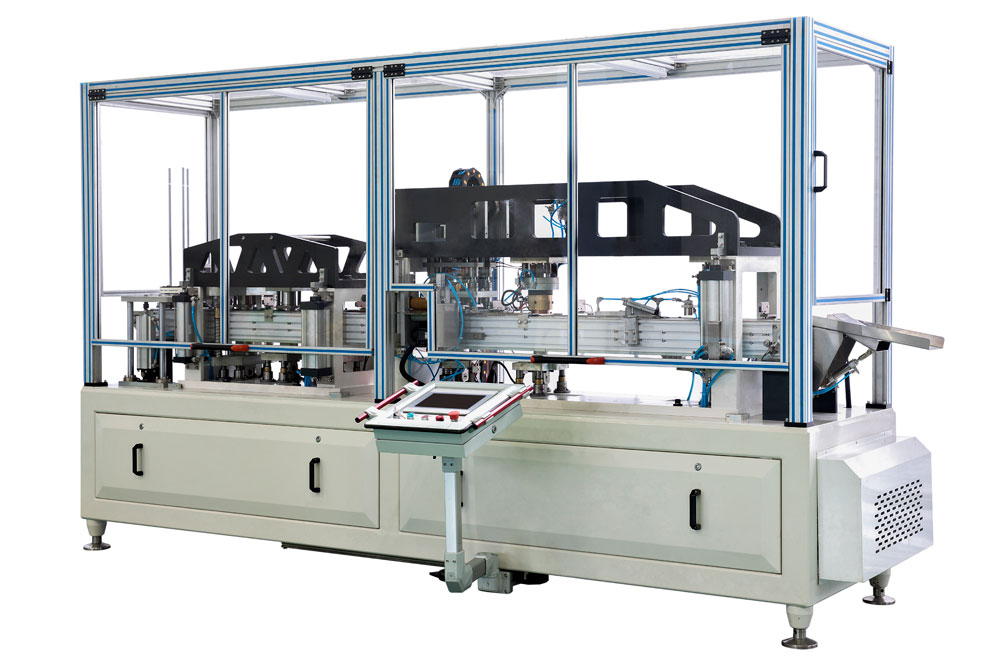

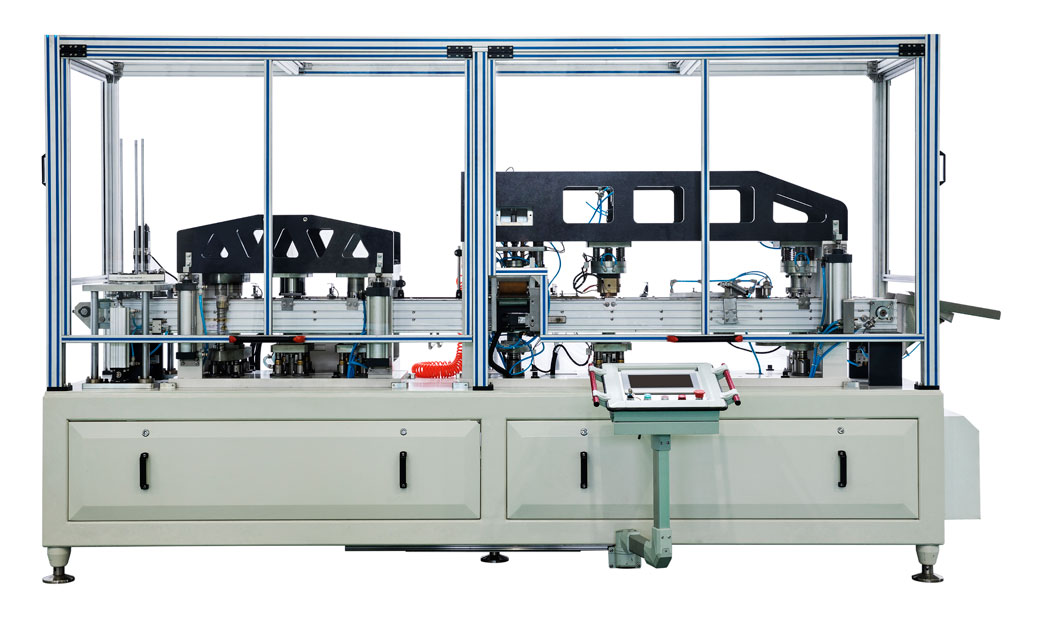

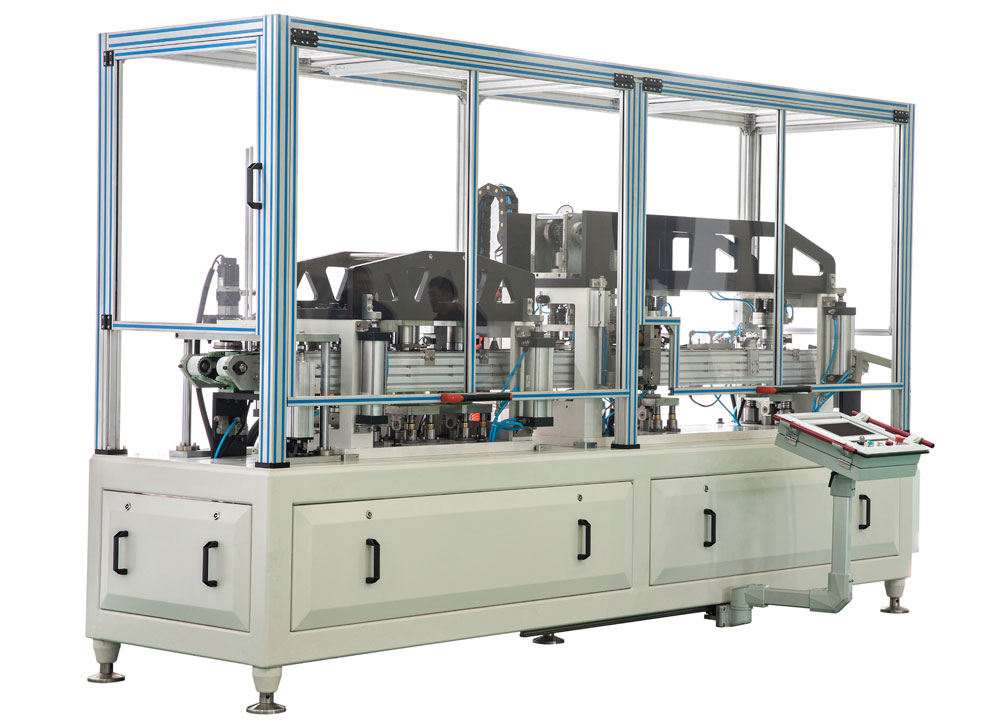

Aluminum foil peel-off ends maker, also known as safety cover, has a wide range of applications, mainly in the field of food packaging. The iron ring has a quick-opening intorted design that does not hurt your hands. The sealing film is easy to open and 50% lighter than ordinary easy-open lids. After the lid is torn to open, no dust or debris will fall into the tank, which will be a high-end packaging form in the future food, pharmaceutical and other industries.

Performance

- The operating system adopts touch screen operation, which can set online parameters

and display various information. - The transmission system adopts the synchronous belt to feed the loop, the servo

connecting shaft synchronous positioning drive, with the balanced sealing pressure, the

whole machine has a precise structure and stable performance, and the sealing film

adopts a cutting method that saves materials. - Preheating adopts high-frequency energy-saving method, and the sealing temperature is

automatically controlled by a vertical temperature control module. - It can automatically complete the functions of lower cover, punching, deep drawing,

crimping, punching aluminum foil pre-sealing, sealing, embossing, output and others. - 1 or 2 lanes design.

Technical parameter

- For making 603, 502, 401, 307, 300, 209 and other customized special-shaped ends

- Production capacity: 120-150epm per lane

- Configuration power: about 50 kilowatts (380V 50HZ)

- Dimensions: about 5000mmx1150mmx2400mm

- Weighte: about 5000KG

- Air pressure: ≥0.6Mpa

- Air flow: ≥0.6M3/Min

Application: